Hardware Operation

MSR (Magnetically Shielded Room)

The Magnetically Shielded Room is designed to shield out or reduce the influence of environmental noise (i.e., the earth’s magnetic field, cars, elevators, etc) on the MEG signal. The walls consist of a layer of a special metal which has a high magnetic permeability (Mu Metal) and two layers of copper. Although the MSR greatly reduces the contribution of environmental noise, it does not adequately shield out lower frequency noise.

Overhead Lighting

- 1. Turn the lights on in the MSR by depressing the square green button on the VAC Power Supply Unit which is located on the bottom shelf of the stand outside the MSR.

- 2. Dimming the lights in the MSR - Use the Brightness (black) knob to dim the light.

-

MSR Light Power Supply

-

Door Operation

- 1. Closing the Door:

- a. Push the door up to the door frame as far as possible.

- b. Press the OPEN/CLOSE BUTTON (Black Button) until the air locks activate and the door begins to close then quickly release the button to seal the door.

- 1. Closing the Door:

- 2. Opening the Door:

- a. Press the OPEN/CLOSE BUTTON (Black Button) until the air locks release and the door begins to open then quickly release the button.

- b. Pull the door open.

- 2. Opening the Door:

- 3. Door Emergency Operation:

- a. Emergency Door Open Button - If the door fails to open, press the EMERGENCY OFF BUTTON (red button) located on the wall outside of the MSR. There is also an EMERGENCY OFF BUTTON located on the inside of the MSR door.

- b. Emergency Door Open Key - If the door fails to open when using the Emergency Off Button, then insert the EMERGENCY DOOR KEY in the upper and lower Emergency Unlock (yellow) keyholes and turn. This will manually release the door locks. Keys and keyholes are located on both sides of the MSR door.

- 3. Door Emergency Operation:

-

MSR Door

-

Oxygen Monitor

- 1. The AirPure Oxygen Monitor is located in the MEG Lab on the wall just outside the MSR (Magnetically Shielded Room). This monitor measures the percentage of oxygen (O2) in the MEG lab; this may be an indication of the air exchange in the MSR and/or the general integrity of the Dewar and related equipment.

- 2. The O2 level should be at about 20.9%. The normal range is 19.5-22%. A reading of 22.0% indicates an oxygen enriched atmosphere which can promote fires (burning); a reading of 19.5 or less indicates an oxygen deficient atmosphere and can lead to a loss of consciousness and/or asphyxiation.

- 3. The alarm will sound if this level decreased below a certain set level; if that happens:

- a. open the door to the MSR and both doors to the lab;

- b. evacuate lab if necessary;

- c. notify the staff scientist and lab director immediately.

- 3. The alarm will sound if this level decreased below a certain set level; if that happens:

Subject Setup and Support

Head Sizing

It is important to first determine if the subject is a good "fit" for MEG based upon head size. This can be done by either measuring the head with a tape measure or using the MEG "Sizing" Helmet. This will determine whether or not to proceed with the MEG Scan. The MEG dewar can fit head sizes up to about 59cm.

- 1. Head Sizing using a Tape Measure: Determines the fit in three dimensions (anterior-posterior, transverse and circumference):

- a. Head Circumference,

- b. Nasion-Inion Distance and

- c. Preauricular Point to Preauricular Point Distance.

- 1. Head Sizing using a Tape Measure: Determines the fit in three dimensions (anterior-posterior, transverse and circumference):

Gantry Limits Nasion-Inion Preauricular Circumference MEG / EEG ≤ 40cm ≤ 40cm ≤ 59cm

- 2. Head Sizing using the MEG "Sizing" Helmet: Always use a protective cap over the head when using the helmet for sizing. The Helmet helps to determine:

- a. whether the subject's head will fit,

- b. how many towels you might need for padding and

- c. how far up in the helmet you can potentially raise the subject.

- 2. Head Sizing using the MEG "Sizing" Helmet: Always use a protective cap over the head when using the helmet for sizing. The Helmet helps to determine:

-

MEG Sizing Helmet-front

-

MEG Sizing Helmet-side

-

Chair Adjustments

The chair is a pneumatic-hydraulic unit and there may be a 2-3 second delay when turning controls from the unlocked to the locked position or when making chair adjustments. After making any adjustment using the hand wheel or valve allow the air pressure to equalize. Turn the hand wheel and valves slowly when making any adjustments.

-

MEG Chair

-

- 1. There are two kinds of controls:

- a. The Hand Wheel which controls the directions and rate of movement and

- b. The Valve which controls which adjustment is selected or activated.

- 1. There are two kinds of controls:

- 2. Chair Movement / Positioning - The Brake Valve locks the chair on the track and thus controls the back and forward movement of the chair; located on the side panel.

- a. Slowly turn the Brake Valve to the unlocked position.

- b. Physically push the chair back or forward so that the subject’s head is positioned directly under the gantry; the back of the head should at the back of the dewar. Check the subject’s posture. Ask the subject to scoot their hips all the way back in the chair so that they are sitting upright in the chair.

- c. After adjusting the chair set the valve to the locked position to prevent movement of the chair. The valve should always be in this position unless adjustments are being made.

- d. Check to make sure the optical cables are not on the track before moving the chair.

- 2. Chair Movement / Positioning - The Brake Valve locks the chair on the track and thus controls the back and forward movement of the chair; located on the side panel.

- 3. Chair Backrest Tilt Adjustment - The upper valve controls the TILT of the chair backrest; located on the front panel.

- a. Slowly turn the Tilt Control Valve to the unlocked position.

- b. Adjust the backrest so the subject is sitting upright in the chair and their head is positioned directly over the hips. It is important make sure the subject is comfortable and therefore reduce the potential for fatigue.

- c. Turn the hand wheel:

- i. Clockwise to make the backrest move forward.

- ii. Counter-clockwise for backward motions.

- iii. Turn the Tilt Control Valve to locked position. It should always be in this position unless adjustments are being made.

- 3. Chair Backrest Tilt Adjustment - The upper valve controls the TILT of the chair backrest; located on the front panel.

- 4. Chair Height Adjustment - The lower valve controls the HEIGHT of the chair; located on the front panel.

- a. Slowly turn the Height Control Valve to the unlocked position.

- b. Position the subject so that his/her head is at or near the top of the dewar. *When near the top of the dewar periodically ask the subject to raise himself/herself up in the dewar to determine how much room is remaining. Do not raise the chair while the subject is rising up in the chair. Ask the subject to relax back down into position that is comfortable for him/her. Then raise / adjust the chair to the subject.

- c. Turn the Hand Wheel:

- i. Clockwise to make the chair move upward.

- ii. Counter-clockwise for downward motions.

- iii. Turn the Height Adjust Valve to locked position unless adjustments are being made.

- 4. Chair Height Adjustment - The lower valve controls the HEIGHT of the chair; located on the front panel.

Positioning the Subject in the Chair

- 1. Before the subject enters the MSR make sure that:

- a. The MEG Chair backrest is upright and the chair is in the forward position so that it is not directly under the MEG dewar.

- b. The Gantry is at 15 degree tilt in the upright (sitting) position.

- c. The Visual Stimulus Screen is in the up position resting against the dewar. If not, move the screen, which is attached to the gantry arm, up out of the way by loosening the black knob on the gantry mounting arm before placing a subject in the chair.

- 1. Before the subject enters the MSR make sure that:

- 2. After setup (placing the fudicial coils, head stabilization towels and any electrodes, if applicable) ask the subject to have a seat in the MEG chair located inside the MSR.

- 3. Place a rolled up towel, covered pillow or covered bolster under the subject's knees and so that the subject does not slide down in the chair.

- 4. If the subject complains about comfort or back support place one or two rolled up towels at the subject's lumbar area. Instruct the subject to adjust for optimal comfort.

- 5. Offer the subject a blanket; place over the subject for warmth.

Head Positioning When Seated

It is important that the subject's head is centered and stabilized (in order to restrict head movement) in the dewar helmet. Currently bath towels are being used for head stabilization in the dewar helmet to prevent head movement.

- Place / drape towels over the subject's head to take up any excess space, placing the bulk of the towel over the areas that have the most excess space. Use as many towels as necessary to take up any extra space in the helmet and restrict head movement, however, this is trial and error. Explain to the subject that "it should feel tight but not so tight as to give them a headache". Ask for feedback.

- With the towels in place have the subject sit in the MEG chair.

- The subject should be seated so that his/her head is midline.

- Move the chair into place - so that the back of their head is aligned with the back of the helmet.

- Elevate the subject in the chair so that the top of the subject's head is as near the top of the dewar as possible while allowing the subject to be able to see any instructions or visual task on the projection screen.

- Instruct the subject to place the back of their head against the back of the dewar helmet.

- Make sure that the subject's head is level, that is, not tilted up or down. If tilted down ask the subject to keep his/her head up. You may place a "chin monitor" if necessary to help the subject keep his/her head in position. Attach tape to each side of the dewar. The tape should just barely touch the subject’s chin.

- Place a Chin Head Movement Monitor using tape to give the subject feedback regarding head movement. *This step is optional.

- When optically positioned all the fudicial coils should be inside the helmet.

- Adjust the stimulus.

- Instruct the subject regarding the task.

- Allow the subject to practice the task, if necessary.

- Begin recording.

- When done recording lower the chair, move the chair forward and place the chair backrest in the upright position.

Installing the Bed for Supine Recording

The gantry should be at a 90 degree tilt for supine recording. There are two gantry control levers which are located on the right (near) side of base:

- 1) the Direction Control Lever and

- 2) the Brake Control Lever

-

MEG Bed

-

- Never operate the gantry while a subject’s head is in the helmet.

- Raise the screen.

- Lower the Gantry to 90 degree tilt (horizontal position).

- Raise the Brake Control Lever (lower / long handle).

- Then raise the Direction Control Lever (upper / shorter handle). This will release the brake.

- Then move the Direction Control Lever in the downward direction.

- Using the Angle Indicator readout located on the gantry near the front pivot point position the gantry at 90 degrees.

- Release the Direction Control Lever to stop the motion. Release the Brake Control Lever.

- Slide the chair forward.

- Recline the chair backrest to approximately a 45 degree tilt.

- Remove the arm rest from the chair. The back cushion may be removed or left in place.

- If the bed will have its angle adjusted place the Roller Wheel Assembly. If the chair back cushion has been left in place, first slide the backrest cushion to its lowest position. Mount the Roller Wheel Assembly to the exposed seat back support plate.

- Two people are required to lift the bed by the ends using the hand grips which are mounted to the under side of the bed.

- Set the bed onto the unpadded armrests of the chair. Align the holes.

- Insert the four mounting bolts, which are tied to the base of the bed, through the holes in the bed base into the holes in the chair armrests.

- All four bolts should be screwed in a couple of turns and fully tightened when all four are engaged.

- Install bed side rail on one side. One side rail must be in place before allowing a subject to get onto the bed. Tighten rail clamp to secure.

- Raise the bed so that it is level with the dewar.

- Slide the bed back so that it rests against the dewar.

- Lift the bed above the optical cables and any other sensitive equipment.

Positioning the Subject on the Bed

Before the subject gets onto the bed, the step stool should be in place against the base of the bed and a guardrail should be in placed on the far side of the bed.

- Place a sheet over the bed.

- Place TWO towels rolled together (lengthwise) at the juncture/gap where the bed meets the dewar.

- Cover the small Foam Pad Pillow and place inside the dewar.

- Place the step stool on the opposite side of the rail to assist the subject in getting onto the bed.

- Place a protective cap over the subject’s head.

- Have the subject sit on the edge of the bed then lie down. Care should be taken so that the subject does not bump his head on the screen or the dewar.

- Ask the subject to bend his knees and use his legs to scoot himself so that his head is inside the dewar. Make sure that the subject keeps his/her head low so that he/she does not bump his/her head on the dewar when sliding in.

- Place a covered pillow or the bolster under the subject’s knees so that there is no pressure exerted on the back, tailbone, or knees.

- Place the head coil cables so that they do not lie across the subject’s chest. Plug into the jack box.

- Once the subject is on the bed, place the side rail on the remaining side. Tighten the rail clamp to secure.

- If necessary, make sure the ancillary mirror has been placed in the 2nd (middle) wall mirror slot.

- The LCD projector image should be reversed / inverted to allow for the extra mirror bounce:

- From the LCD Projector touchpad (or using the remote):

- - Press MENU.

- - Press / to select the “PRJ Mode”.

- - Press / to select desired projection mode (Rear / Reversed image).

- - Press MENU to exit.

- Re-position the ceiling mirror. Adjust the wall mirror.

- Begin Data Acquisition.

- When finished, remove the bed, move the chair forward, place the backrest in the upright position, replace the arm rest and back cushion.

- Position the gantry at 15 degrees.

Head Positioning When Supine

- The subject's head should be as close to the top of the dewar as possible.

- Make sure that the subject's head is not tilted down; use a towel roll placed under the neck (in the groove where the bed meets the dewar) to make sure that the subject's neck and shoulders are supported. Adjust as needed.

- Ideally, all fudicial coils should be inside the dewar helmet for optimal placement.

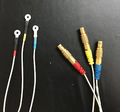

Head Coil Cables

Plug the Head Coil Cables into the appropriate color-coded locations on the DSQ 3500 Amplifier Head Localization Module located on the stand next to the dewar.

- −Note: If the head coil cables are placed in the wrong jack or placed on the wrong anatomical location the coil locations will be skewed and the calibration will fail. Repeat the calibration after changing the jacks the correct location in the jack box or switching the coils to the correct location on the subject.

- −Route the right Head Coil Cable around the back of the subject’s neck so that it does not lie across the subject’s chest. Route the other two cables in front of the subject’s neck so that they do not touch the subject’s chest.

Head Coil Cables Nasion Right Ear Left Ear Yellow Red Blue

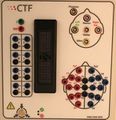

Mounting the Electrode EasyCap JIF Connector

The VSM EEG EasyCap System can accommodate up to 56 electrode positions.

Mounting the Electrode EasyCap JIF Connector onto the DSQ 3500 Amplifier when performing EEG:

- Touch the Static Discharge Button on the Amplifier Unit.

- If the Gain Calibration Card (Shorting Plug - small green circuit board) is situated on the Amplifier Unit, carefully remove it before connecting the Electrode Jack Box.

- Connect the Electrode Cap JIF Connector to the DSQ 3500 Amplifier Unit. Align and press down firmly.

Connecting EEG Electrodes to the Amplifier

When using individual electrodes to perform EEG you can perform unipolar and / or bipolar recordings.

- *If performing a Unipolar Recording - plug the electrodes into the appropriate jack within the head diagram. There are 21 unipolar jacks/channels located on the DSQ 3500 Amplifier. These unipolar channels measure the difference between the electrodes and a common reference channel. The reference channel is common to all of the EEG unipolar channels.

- *If performing a Bipolar Recording - plug the electrodes into the bipolar module on the DSQ 3500 Amplifier. There are 8 Bipolar Channels which measure the potential difference between two individual electrodes. These channels are not numbered on the amplifier. They are labelled channels 056 to 063 in the acquisition parameters and channel 56 corresponds to the 1st bipolar channel on the amplifier and so on through channel 63.

- DSQ 3500 Amplifier Bipolar Channels Designations

DSQ 3500 Amplifier ACQ Channels 1st Channel 056 2nd Channel 057 3rd Channel 058 4th Channel 059 5th Channel 060 6th Channel 061 7th Channel 062 8th Channel 063

Subject Monitoring Inside the MSR

The subject must be observed at all times when inside the MSR. Always monitor the subject via the Video Display Monitor when running a study. The operator can converse with and monitor the activities of the subject inside the MSR by:

- Voice Intercom Electronics Box / Apex Unidirectional Dynamic Microphone / Parabolic Microphone / Flat Speaker System - Used to communicate and listen to a subject inside the MSR. The Intercom Electronics Box and Dynamic Microphone are located at the acquisition workstation / operator’s console. There are no intercom controls inside the MSR, just the parabolic microphone and flat speaker.

- - Press the Red power button to turn on the Intercom Electronics Box to listen to a subject inside the MSR.

- - To speak to a subject who is inside the MSR press the PUSH TO TALK button located on the front of the Intercom Electronics Box.

- - To hear the subject who is inside the MSR release the button to hear the subject talk.

- - Adjust the volume in the MSR or at the Console by using the volume control knobs located on the front of the Intercom Electronics Box.

- Infrared Lighting - for video in darkness. Illuminates a subject inside the MSR when recording in a dark environment so that the subject may be seen via the Video Display Monitor. The Control box is located on the stand outside the MSR.

- - Press the Red On/Off switch to turn on the power for the Infrared Light Power Supply (SEC 1212).

- Video Cameras - Used to view subjects inside the MSR on the Video Display Monitor.

- - There are 3 cameras located inside the MSR.

- - Cameras can be re-positioned manually.

- Video Display Monitor - Used to monitor a subject inside the MSR. Located at the acquisition workstation / operator’s console.

- - Press the on/off switch located on the front panel of the Video Display Monitor.

- - Press the channel button once to access the next channels.

- - Continue to press to access other channels.

Video Display Monitor Channel 1 Camera 1 Infrared Camera Channel 2 Camera 2 Color Channel 3 Camera 2 VCR Playback (connected to Color Camera) Channel 4 (Blank)